Considering Change Management

Digital Transformation Stories from the Field

As more and more of our clients recognize the value and often the necessity of digitizing their operations, the topic of change management inevitably comes up.

I am currently on a project team helping a chemical polymer company deploy a new digitized operations management software. The expectations for this new technology is to improve the accuracy and efficiency of business processes and procedures. It is assumed that digitization of operations will reduce human errors and if done correctly, that will be true. This software is replacing a mostly paper-based system that has been in use for over 40 years. For this job, our team needed some basic background information to be effective:

-

- Which technology has been chosen and why? What is the capability of the software?

- What does the current business process look like? Are there known problems we are trying to address?

- How large is the plant? How complex is the process of manufacturing?

Knowing the answer to each of the above questions was helpful in building the overall picture of just how much effort and resources would be needed…..but it was just scratching the surface. There were several other details my team needed to make the project successful:

-

- How many business processes will change due to the new digital technology?

- How many stakeholders are there? Is there a common understanding of project expectations?

- What are the operator’s demographics and how digitally savvy are they (In general, the blend of older and younger workers affects the time of transition to new methods)?

- How does plant leadership embrace change? (Often times workers reflect leadership’s attitude)

- How many people will need to be trained? What shifts do they work? (Rotating, stable, M-F, weekends, days/nights)

Most project plans incorporate, or at least acknowledge, the answers to the background questions above. But the less obvious second set of questions start to get at how people are really affected. Usually there is not enough thought given to these questions. The people component of a project plan has direct influence on the overall success of the project. How the new tools will be utilized ultimately determines the level of sustained success.

All of the aforementioned is intended to get the reader thinking about the scope and importance of change management.

Let’s tie this back to the current operations management project work mentioned earlier.

My customer recognized the need to modernize their operations management environment. As mentioned, they currently depend mainly on paper, SharePoint, Excel, a mix of other good technologies, tribal knowledge, and solid leadership. As we began to build the new process it has become clear that they may have missed a step. We vitally needed to listen to and incorporate the voice of the internal customer, VOC. In this case, the internal customers are the operators and controllers who operate the plant 24/7/365.

Everything related to internal communications and recording of equipment data is being affected one way or another with this deployment. So, although the internal team of project leaders and process experts I am working with understand the plant very well and are great to work with, they are not the ones who will ultimately be using the system. Specifically, the change(s) being managed include:

-

- Shift Handovers

- Inspection Rounds

- Operational Logbooks

- Plantwide Communications (Standing Orders)

It needed to be determined how fast the expected changes could be absorbed by operators and controllers. Which tools are to be rolled out and used now vs to be used in the future? Which tools will change? Which tried and true current methods can we incorporate into the new process? These types of considerations had to be applied across shifts, areas, and individuals.

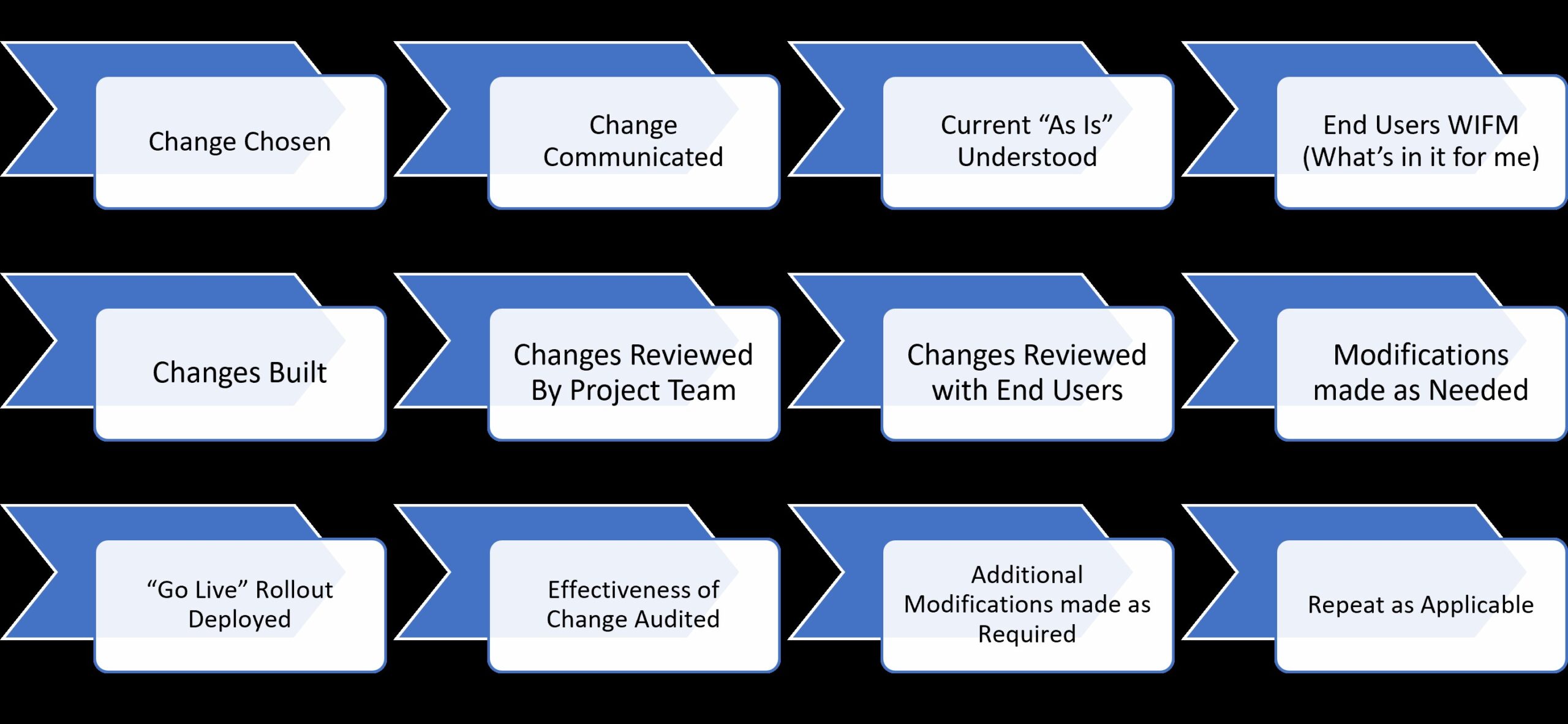

As we can see, there is plenty to manage here! Luckily we recognized the dependence on the end users in the configuration of the various categories of change above. Here’s how I picture what’s been discussed so far:

Final thoughts:

Manufacturing digital transformation projects can be very impactful because they touch a wide variety of people and areas. As the transformation process continues to expand, the ownership should grow right along with it. Change management done correctly is not easy but is highly rewarding. The ultimate reward is a workforce that better owns new and improved processes and recognize the outcomes they are creating. Relationships up and down the organizational chart improve and this, in turn, sets the stage for inevitable future changes and on-going success.