Why You Need a Digitization Strategy?

If you didn’t make it to the recent ISA Energy and Water Conference (EWAC) in Orlando, we wanted to share a small snippet of what you missed.

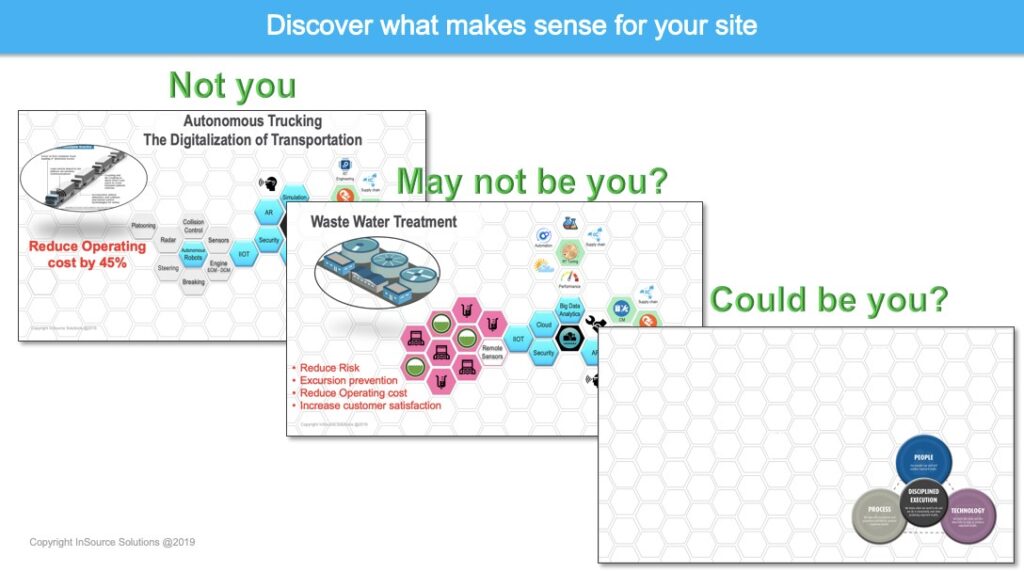

Today’s digitization movement impacts everyone in a slightly different way. There is no single slam-dunk idea or industry 4.0 technology that will solve all the challenges of industrial users and manufacturers alike. The water and wastewater industry has challenges that are different from an electric utility, which are different from a tier two automotive parts supplier, which are different from a consumer products manufacturer. Most of us realize that the statements above are true but, as a community, we often speak of digitization in such a generic fashion, we tend to leave listeners unclear of what’s real for their specific industry and what can be easily operationalized.

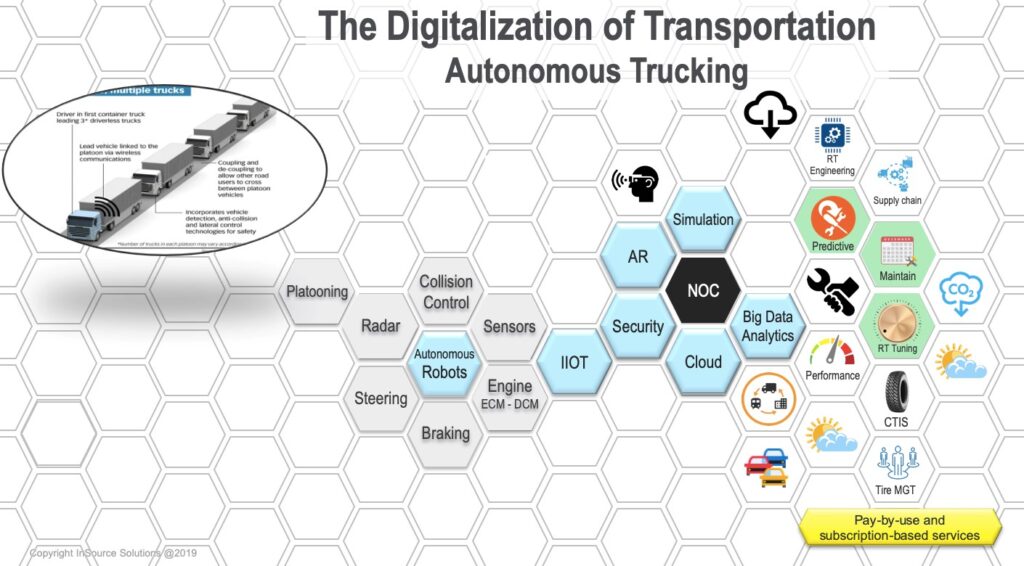

At the EWAC event, InSource used the example of autonomous trucking to show how the latest digital technologies are being deployed to solve big challenges in transportation. 63% of consumer goods are trucked to market while there are 50,000 vacant driver seats in the industry. By 2022 that number is expected to be 250,000 since younger generations don’t see truck driving as a viable career. This is a huge problem facing the industry and impacts between 85 and 120 billion dollars in operating cost annually. Autonomous trucking is in the future, no question about it, and transportation companies will use much of the same technology to achieve it as we would in a water treatment plant, electric utility, or consumer products manufacturer.

It’s a cool time to be in an industry where a remarkable number of solutions are being made available which can make a significant impact on how we operate and manage the industrial systems that drive our economy. Whether you call it Industry 4.0, X.0, or some form of the word “digitization” it really doesn’t matter. What matters is whether we can identify and put into operation some of these solutions to benefit our organizations.

No matter the vertical sector, two areas are universally high priority targets for digitization efforts:

- Better management and preservation of assets

- Better management of labor

Manufacturing and industrial sites have the most expensive assets of any sector across the economy, yet they are among the least digitized. Low asset digitization means less ability to monitor and manage assets to ensure maximum up-time, optimize performance, and maximize asset life cycles. Organizations have been refining their asset management strategies for years with advanced computerized maintenance management systems (CMMS) and continuous improvement methodologies such as TPM and PM programs. Now advancements in technology are further improving asset management by utilizing more sensors, data, artificial intelligence, and machine learning to predict bad behavior weeks and months into the future. This is huge! To know four months ahead of time that a million-dollar piece of equipment is 80% likely to fail makes all the difference. We can now set into motion our plan to avert that failure. We can coordinate a plant outage on our terms – not the equipment’s terms. We can have our equipment experts and factory representatives onsite and ready. We can have all the parts required for repair on-hand.

On a complicated piece of equipment, the number of parts that may need replacing could be significant and costly. How do you know which parts to order? Predictive analytics solutions, like PRiSM from AVEVA, not only give you the heads-up on what piece of equipment will fail, it gives you a prescription of which part is likely to be the root cause. Armed with this information, we buy only what we need for the equipment outage.

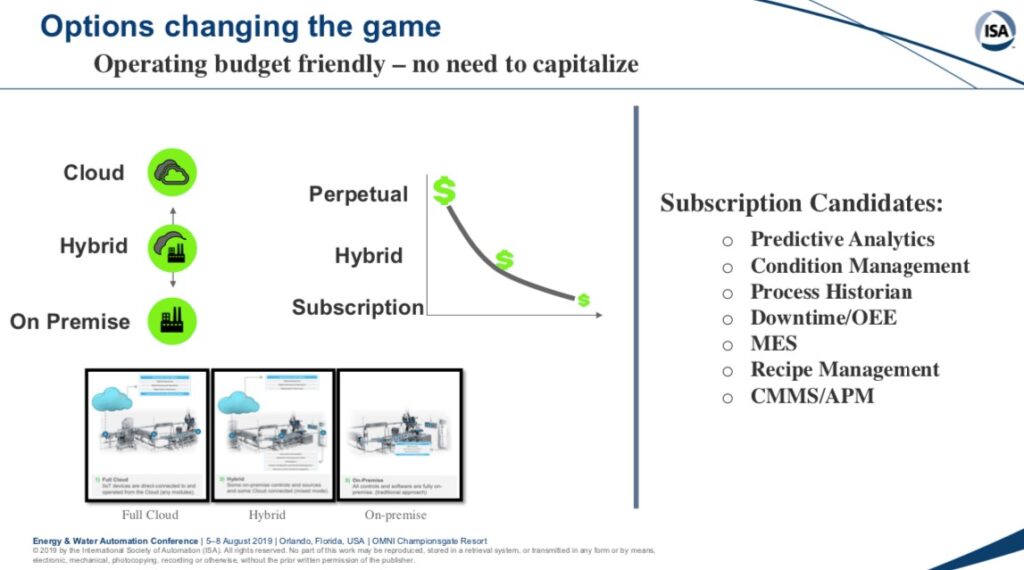

You may say to yourself that this type of predictive analytics technology isn’t brand new and its cost is outside of what most manufactures or industrial user can afford; that may be have been true in the past. However, this type of solution is more affordable today through new licensing and deployment options. Subscription licensing and cloud deployment are game changers with this type of solution because it doesn’t require huge capital and infrastructure to operationalize.

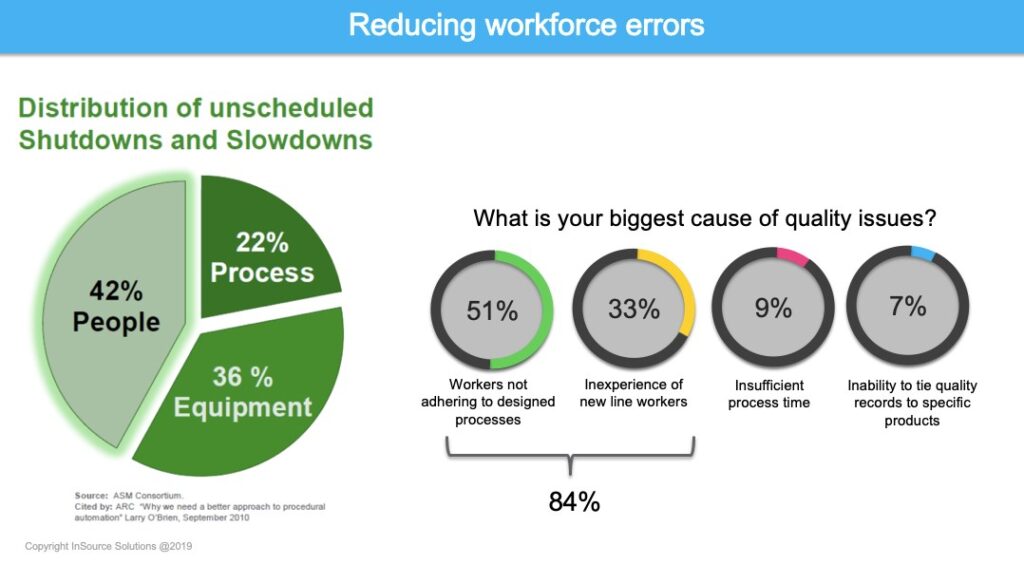

The other high priority target is the digitization of labor. This is significant for several reasons and may differ throughout vertical sectors. What people do inside the plant is one of the least digitized areas. “People” in this case includes operators, maintenance, quality, supervisors, leadership, safety, etc. – virtually anyone performing activities that are part of the value-chain of the industrial process. Studies show that people are responsible for 42% of slowdowns or shutdowns on the plant floor and responsible for a combined 84% of quality issues. Yet, what people do and how they do it is one of the least digitized functions in our industry.

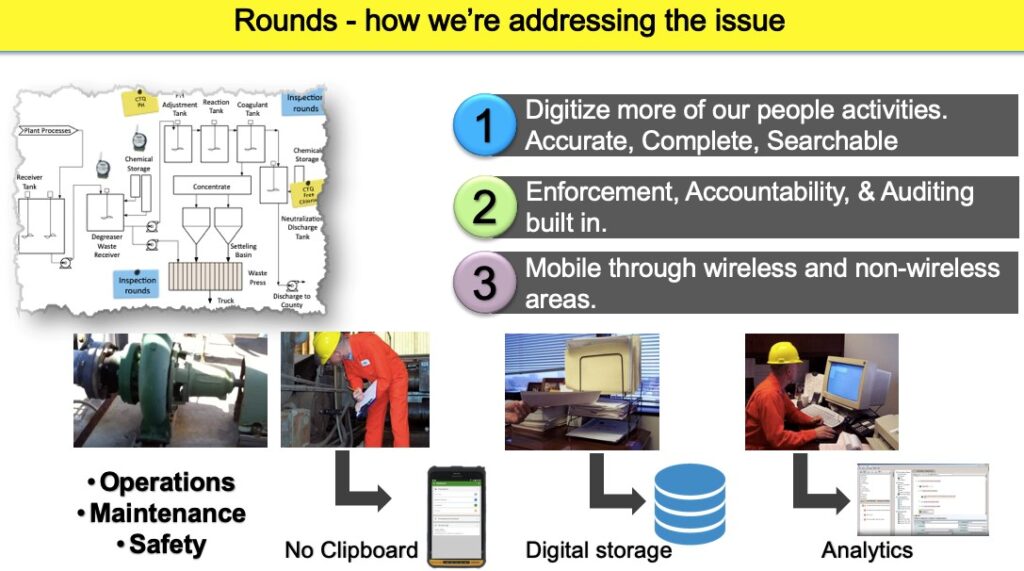

Too much of what we do in industry is hand written in log books and spreadsheets, lending itself to errors, low accountability, and partial information that is non-searchable, non-reportable, and non-shareable. On top of that, with the exit of senior subject matter experts at every site, capturing their tribal knowledge for new employees is an imperative. Many industrial users are advancing their organization by investing in tools that help digitize work processes. These systems help by creating daily work lists for all teams on each shift, enforcing and documenting operator and maintenance rounds, publishing and validating standing orders for all employees, and automating procedures for all “people” activities. All this information is then put into context in a single tool where one version of the truth for that shift can be viewed by all stakeholders. Regardless of where the data originates (the lab, the control room, a Gemba walk, a maintenance worker, a supervisor, the control system or a historian database), all information can be seen on the same tool on multiple platforms (i.e. desktop, mobile phone). Users all over the world are using digitization strategies to optimize their organizational labor force.

During the EWAC, we challenged everyone, regardless of vertical industry, to get into the modern digitization game. During this season, the advancement of technology provides a unique opportunity for all. Autonomous trucking may not be your focus, but the impact can be just as significant. Regardless of your plant type, take a blank sheet of paper and start defining your digitization strategy for the next three to five years. For individuals with influential roles at your site, doing so will help expand your collective thinking and help create a vision and purpose for everyone in the plant. Digitization initiatives can be game changers both in hard and soft terms (i.e. dollars of ROI and soft impact, like culture). They can help to align, prioritize, and focus your entire organization.

This is what InSource does every day for users in every vertical imaginable. If you are interested in starting that digital journey and need help defining what to put on that blank piece of paper, we would value an opportunity to be a part of your team.

Click here to download InSource’s 2019 EWAC keynote presentation