The Next 25 Years in Manufacturing Industry Transformation

Buckle Your Seatbelts

InSource just celebrated our 25th anniversary. It’s a significant milestone and I’m so proud of our team and what they’ve accomplished since our inception in 1997. It’s been quite the fascinating journey. Allot has changed in our industrial automation marketplace. It has caused me to stop and reflect on what’s next for our world, U.S. manufacturing in general, and industrial automation in specific for the next 25 years.

Spoiler alert: It’s going to be a wild ride. Buckle your seatbelts.

The Past 25 Years

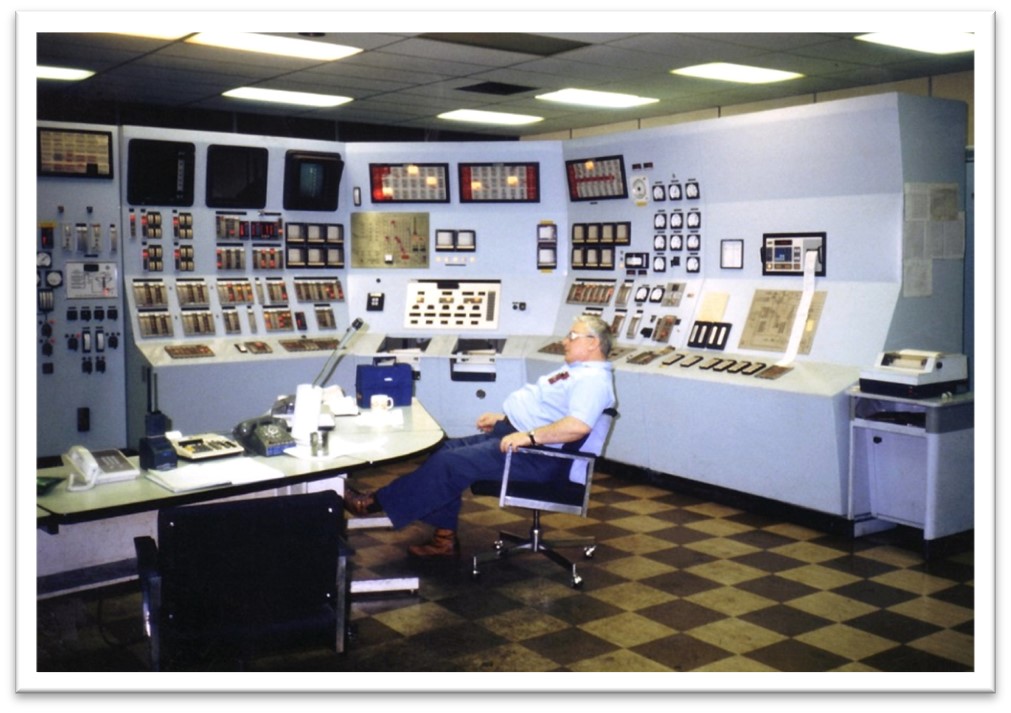

In 1997, factory automation essentially still looked like this: a collection of disconnected analog and digital tools, dependent on field expertise for interpretation and action.

Unbeknownst to us at InSource, a burst of rapid change was on the horizon. Although not the perfect analogy, the evolution of cellular phone technology for the 25 years between 1982 & 2007 was similar to our last 25 years in manufacturing industrial automation and perhaps a bit easier to visualize.

Behind the scenes, a similar evolution was happening in industrial automation, albeit offset by 15 years. (As an industry, we don’t like “bleeding edge”) These changes went by allot of different buzzwords, i.e., industry 4.0, smart manufacturing, manufacturing renaissance, industrial revolution… but today’s equivalent of the modern iPhone in industrial automation looks something like this:

AVEVA Unified Operations Center

And just like the iPhone, the real innovations happened behind the scenes.

Industry 4.0 Innovation Impact?

We know from U.S. manufacturing history that every sustained period of U.S. economic growth has been launched by a manufacturing innovation behind the scenes: steam engine in 19th century [Industry 1.0]; mass production in the 20th century [Industry 2.0]; 1st wave of factory automation including Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCS) in the 1970s [Industry 3.0]. But after the 70’s we went through a long period of stagnation. Industry 4.0 Technologies such as IoT sensing, Robotics, Cloud Computing, Artificial intelligence continued to advance, but manufacturers were slow to embrace them, often pursuing other paths for profits and productivity gains, such as offshoring production, reducing inventories in favor of Just in Time (JIT) production, extending supply chains, or even divesting themselves of their manufacturing divisions in pursuit of “the service economy”. On the ground at InSource, we saw transformational digitalization and automation projects being scoped, but delayed as management often had a hard time “pulling the trigger” on such modernizations.

As a result, 75% of U.S. plants are more now than 20 years old. These facilities built before 2000 and in some cases WAY before 2000, are surviving and competing by making the necessary repair or replace decisions every day. Until recently they didn’t believe they had the mandate or ability to tackle more.

A Tipping Point in U.S. Manufacturing History

But then came COVID to give us all the “nudge” we needed. The reality on the ground turned hypotheticals into action plans. It has literally been the “Tipping Point” for our industry. Now COOs and Plant Managers are wrestling with the forecasted major shifts in our world over the next 25 years and gauging how to respond. They, in consultation with industry advisors, are creating industry 4.0/5.0 digital transformation plans to not only address their aging infrastructure, but also address:

- Major shifts in the workforce: Generational shifts, remote work, accelerated retirements and quits

- Supply chain uncertainty and disruptions

- Accelerating their energy transitions to electrification & measures to minimize environmental impact

- Inflation and rising raw material costs

- Rapidly changing consumer preferences & demand patterns

If Digital Transformation Plans are done correctly at this Tipping Point moment, we can be ready for 2050 by addressing these challenges and simultaneously reinvent U.S. Manufacturing.

The Next 25: Re-invention for the Next Generation & New World Dynamics

To underline the importance of these planning efforts, I’d like to examine five 2050 predictions for our planet and how Digital Transformation planning in the industrial arena is needed to respond. And btw, these predictions are big. If only 3 of the 5 listed here happen, the ripples will be wide. (1)

- Universal Connectivity – By 2050, it is likely that 100% of the world’s 8 billion inhabitants (most of those people living in Asia & Africa) will be connected via the internet. By 2030 alone we should see 2.5 billion connected cars(2), 400 million smart homes(4), over 500 million wearable units shipping annually(5). The 115 million smart meters currently installed in the U.S. (3) should grow to over 1 billion smart meters worldwide by 2030. This vast web of connection creates a planet-scale market for commerce, audience for ideas and source of remote workers. A start-up in a small country in Asia now has a greater chance than ever of having a billion-person customer base. A technology provider in Indiana can harness a resident genius in Nepal with ease. Think that unlikely? Many fantastic youths in far-flung places may have all the coveted skills required by a remote employer — except the skill of English. Universal real-time language translation in ear pods — which will be available in a few years — will solve that problem and unleash the skills of billions.

- Sustainable Energy – We will successfully shift to a sustainable energy infrastructure using solar, wind, hydro and nuclear. Studies have indeed shown that it’s theoretically possible to achieve 86% reduction in energy related CO2 emissions in U.S. manufacturing by 2050. (6) Leading companies across major CO2 emitting industries, such as energy & utilities, steel, and transportation, have announced their decarbonization commitments for either 100% Renewable Energy or Carbon Neutrality or Net Zero Emissions. This will shape allot of enterprise projects over the next 25 years as there is major work to be accomplished.

- Near Total Urbanization – By 2050, most of the planet will live in urban areas. Today half the world lives in a city. That is expected to be 70-80% by 2050. Big cities are tackling the same issues that our smart homes are (security, lighting, sound, temperature, utility consumption) at a massive scale. Sustainable designs are paramount. To optimize emergency response routes, waste collection logistics, air quality, traffic congestion, public energy usage, these “Smart Cities” must modernize infrastructure from the ground up and include industry 5.0+ technology, data acquisition and models to streamline everyday urban life.

- Ubiquitous AI – Artificial intelligence will finally be embedded into our everyday lives with new products never before imagined and a resulting restructure of which jobs are best suited for humans. In the industrial world, that will mean a surge in guided and predictive analytics for operators and production practitioners. The type of “what if” simulation that has had limited widespread application to date will be commonplace. And of course, we will have to learn to trust these insights…. Just like my journey with Google Maps, many of us feel most comfortable with the technology we know and trust. In my case the Rand McNalley Road Atlas in the 80’s and my self-espoused keen sense of direction was hard to let go of. So, let’s just say it took me a while. But today, I trust the technology and use Google Maps to find the quickest way to the mailbox.

- Generational Handoff – You may have been warned about the “Aging Tsunami.” It’s real. The world-wide Boomer generation (which I am one of the youngest) will be retired as will many of the Gen X’ers. The next generation will come of age by 2050. Millennials (those born between 1981 – 1996) became the largest group in the workforce in 2016 and by 2035, people over 65 will outnumber people under 18 for the first time in history. (7) So, by 2050, those of you now 25-40 will be firmly in charge. This is good news for the world. You are accelerated learners with access to free online resources. You are very civic-oriented and will be eager builders. In general, you are more optimistic than Boomers and won’t be asking permission to drive change just at the time it is needed.

- Speaking of the Skills…. Over the next 25 years, there will be a dramatic change in the skills, roles, and jobs needed in manufacturing. Up to 75% of the manufacturing jobs in existence today could be obsolete by 2050. In fact, 2.1 million unfilled jobs are predicted by 2030.(8) At all levels, whether you’re talking about assemblers, machinists or industrial engineers, workers will need to be more proficient in technology skills like industrial networks & controls and statistical analysis or manufacturing specialty skills like robotics and automated equipment design or human skills including decision making and problem solving through the mastery of data, ability to manage multiple teams and augmented reality development & testing. It’s gonna be different and companies will need to hire, re-train and outsource differently.

Innovators Wanted

In summary, the next 25 years in manufacturing and industrial automation will be where rapid, meaningful change takes root and an incredibly exciting place to be. One reason the change will be so fast is that many of the foundational technologies are already here. Nonetheless, they are not deployed, nor adopted at scale…YET. We’re in for a wild ride and are woefully short of the number of entrepreneurs and STEM enthusiasts to boldly take the handoff from today’s leaders and start to address these challenges head on. It’s more than possible, it’s necessary, and it’s what we’ve been waiting for. Fasten your seatbelt, step on the accelerator. Let’s go!

Sources:

(1) WarpNews, “The Case for Optimism” Kevin Kelly Feb 8, 2021

(2) Transformation Insights, “Connected cars will hit 2.5 billion connections in 2030, driving cellular IoT and 5G adoption” JUN 30, 2022 | Matt Arnott

(3) Statistica, “Number of smart meter installations in the U.S. 2007-2021” ,N. Sönnichsen, Jun 21, 2022

(4) Comfy Living, “30 Smart Home Statistics for All High-Tech Enthusiasts” Ljubica Cvetkovska, January 10, 2022

(5) Deloitte Insights, “Wearable technology in health care: Getting better all the time”, Dec 2021, Jeff Loucks

(6) Utility Dive, “To decarbonize industry, DOE road map focuses on efficiency, electrification and low-carbon fuels” Robert Walton, Sept. 8, 2022

(7) U.S. Census Bureau, “Older People Projected to Outnumber Children for First Time in U.S. History”, Tuesday, March 13, 2018

(8) NAM Newsroom, “2.1 Million Manufacturing Jobs Could Go Unfilled by 2030” May 4, 2021