Manufacturing Execution System

Manufacturing execution systems (MES) ensure that all facets of an operation — materials, people, processes, and equipment — act in concert, securely, and in compliance with industry, customer, and product specifications. AVEVA MES system enables agile, short-term production planning and flexible update schedules. It also improves supply chain visibility and decision support by updating business applications with production responses and KPIs in real-time.

We don’t just provide MES software, we deliver turnkey MES solutions. From design and deployment to training and ongoing optimization, our professional services ensure your MES investment translates into operational excellence.

Features

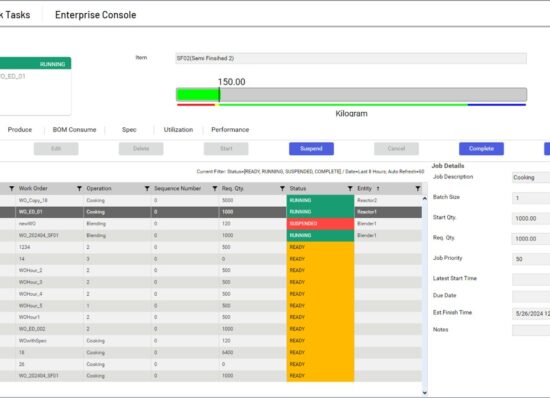

Real-time production control

Manage plant schedules and execute work activities with up-to-date production and inventory status information. Quickly respond to unplanned events and minimize plant downtime.

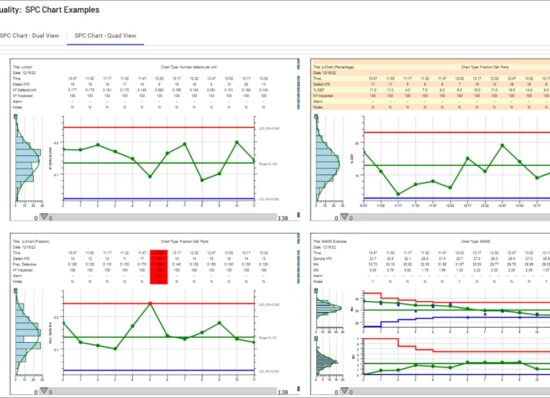

Process and product quality monitoring

Automate quality sample plan execution. Apply Statistical Process Control (SPC) methods to visualize quality data and KPIs in real time. Easily identify samples that violate limits and rules.

Cloud integration

Store, share, and visualize execution data in the cloud. Integrate data from multiple plant MES systems. Enrich with data from AVEVA™ PI System™ and other OT and IT data sources.

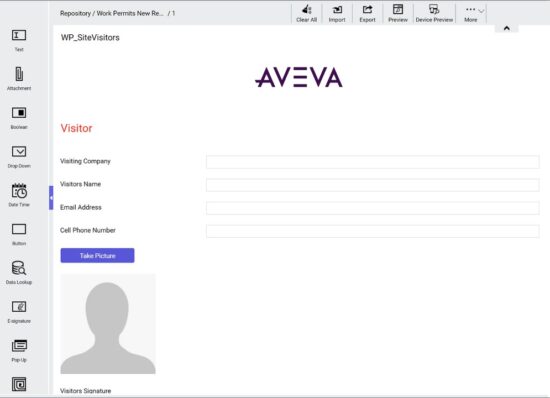

User experience modeling

Adopt information views to your work practices with a low-code HTML5 forms designer. Include schedule adherence and real-time OEE KPIs with decision support to maintain production performance and line throughput.

Plant modeling

Model your plant processes and business rules. Guide workers with process, product, and quality specification information and validation for the current scheduled job. The model abstracts from physical processes and provides a consistent user experience for operational activities.

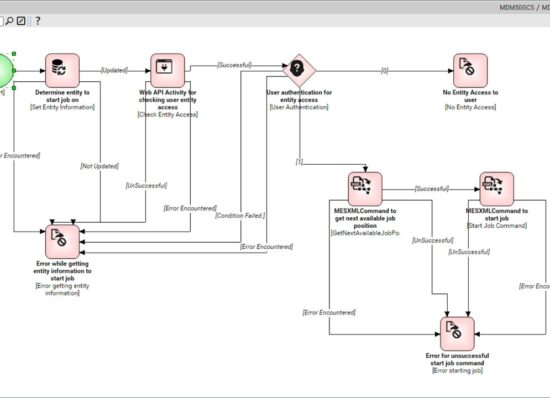

Digitalization of workflows

Capture operational procedures and workflows using low-code technology. Automate and ensure correct and consistent workflow execution. Transform and standardize how work is done in the plant with a digital user experience on desktop and mobile devices.

AVEVA Model-Driven MES Product Page

Brochure, customer stories, demos, and more.

Multisite Manufacturing Execution System Standardization

Shorten time to value and reduce ownership costs for your smart manufacturing initiatives. AVEVA’s edge-to-enterprise MES solution allows operations to scale while offering a sustainable, model-driven approach. Standardize your lean and continuous improvement best practices, operational processes, KPIs, compliance reporting and supply chain integration across multisite operations.

Drive consistent manufacturing practices across your organization by standardizing technologies and processes for measuring plant efficiency and enforcing regulatory compliance. By gaining visibility into plant operations, you enable a more responsive plant and more agile supply chain operations.

- Model-driven standardization captures best practices in templates and libraries that can be rolled out and adapted across multiple sites

- Ready-to-use standard MES activity and user interface models reduce time to value for plant MES solutions and multisite standardization projects

- An edge-to-enterprise architecture reduces the cost of multisite MES standardization and unlocks business-wide benefits

Related Products

Get Started With InSource Today

Take the first step towards increased productivity and profitability.

Latest Updates

-

Event

Workshop: Unlock Hidden Process Gains with Braincube [Invite Only]

19 Mar, 2026 -

Resource

InSource Solutions Group Announces Acquisition of AVEVA Select California, Expanding Its Reach to Become the Largest AVEVA Select Partner in the Americas

-

Blog

Internships at InSource Solutions

-

Blog

Influence In The Industry – Aaron Evans