Workforce Optimization

-

Why No One ‘Wants’ to Work

Newer generations… …“just don’t have a good work ethic.” …“aren’t willing to put in the hard work.” …” have no sense of company loyalty.” Does this sound familiar? These are… -

The Connected Worker Culture Shift

Steve Jobs’ introduction of the Apple iPhone in 2007 was nothing short of revolutionary. But contrary to what our perception of that announcement may be now, there was quite a… -

Solving the Labor Shortage Conundrum in Manufacturing

A Case for Digital Onboarding & Training It is no secret that many industries around the world are struggling with labor shortages. Especially hit hard have been manufacturers. I’ve spent… -

Considering Change Management

Digital Transformation Stories from the Field As more and more of our clients recognize the value and often the necessity of digitizing their operations, the topic of change management inevitably comes… -

MES and Connected Workers. The Next Gamechanger.

Part 1 in a series on Adoption Tips & Tricks. The Manufacturing Execution System (MES) umbrella of functions is quite broad and the benefits in productivity, efficiency, as well as… -

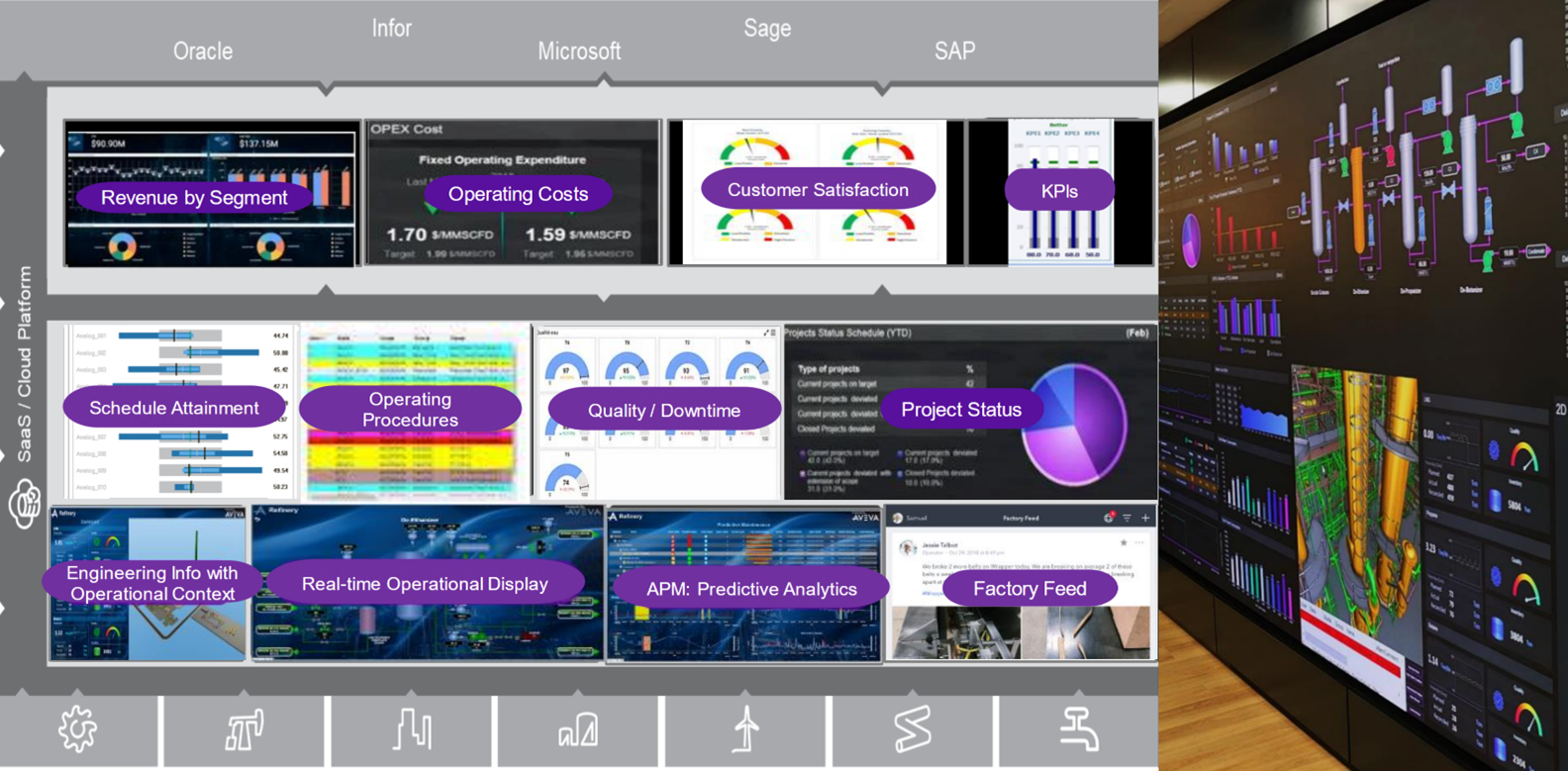

The Drive to Unify

Transforming operations by increasing visibility and access to actionable information. Many of our largest clients are knee deep in active Digital Transformation initiatives. As they execute on these projects, they… -

Exciting Innovations allow InSource Services Teams to maintain “The Touch”

Meet, Deploy & Train Remotely Covid – 19 has changed the way we engage with our customers since 2020 and most likely forever. Because of Covid – 19 safety protocols,… -

Layering Smart Data Solutions

Analytics for Summer, Fall, Winter, Spring…. If you live in an area where the weather has distinguishable seasons, in your home there is one closet that is jammed with coats.… -

How Manufacturers Can Build “Growth Rings” For Digital Transformation Roadmap Blog

Start small and build out layer by layer over time A tree in my backyard, a White Oak, stands 102 feet tall (at least as measured by my Golf Rangefinder)…

- 1

- 2